Thermography

Advanced thermal imaging solutions for power maintenance, machine vision, building inspection, industrial monitoring, and medical diagnosis applications.

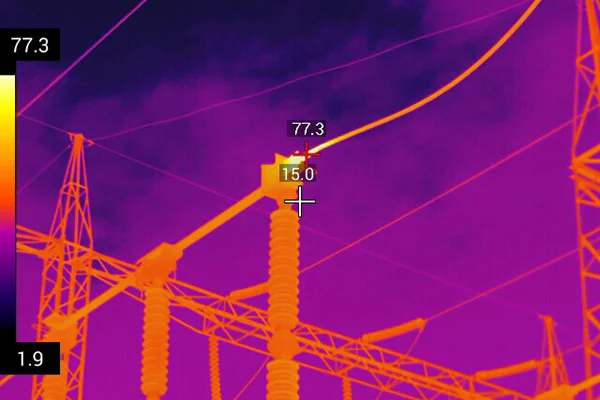

Power Maintenance

Thermal imaging technique is an advanced technology for diagnosing hot spots in substations, transmission lines and distribution networks. It plays a key role in finding, preventing and handling accidents in the power industry. Infrared technology gives us the ability to "see" and measure temperatures on defective components and detect normal wear, chemical contamination, corrosion, fatigue and faulty assembly in electrical systems.

Solution

On-line Monitoring Systems, Robots, Portable Thermal Imagers, UAV Payloads

Key Features

- Support LAN interface: Gigabit Ethernet adaptive, hundred meters transmission

- High precision temperature measurement, adjustable temperature range

- Professional thermography analysis: regional analysis, multi-spots temperature measurement

- Isotherm, high temperature alarm, hot spot automatic tracking

- Optional wide angle lens

Machine Vision

Machine vision carries out measurement and makes judgment instead of human eyes. Infrared thermal imaging enables machines to "see" the invisible and carry out non-contact temperature measurement accurately, fearless of smoke, dust, glare, back-lighting etc. It can be applied in process instruction, packing, sorting, moisture detection, contamination monitoring, and abnormal temperature measurement.

Solution

On-line Monitoring Systems, Robots, Nondestructive Testing

Key Features

- Support LAN interface: Gigabit Ethernet adaptive, flexible network

- High precision temperature measurement, adjustable temperature range

- High frame rate at window mode for nondestructive testing

- High sensitivity detection

- Wide angle lens options

Building HVAC

If buildings have design defects such as unqualified insulation, hollowing, or moisture, they usually cannot be detected by naked eyes. Infrared thermal imaging technology identifies building safety from surface temperature distribution. It detects defective insulation, electrical failures, water seepage, pipeline issues, and mold.

Solution

Portable Thermal Imager, Smartphone Plug-in Thermal Imager

Key Features

- Professional thermography analysis with multi-spots measurement

- Pseudo-color visual enhancement for slight temperature differences

- Walls and pipes details clearly visible

- Extremely tiny and lightweight design

- Low cost integration

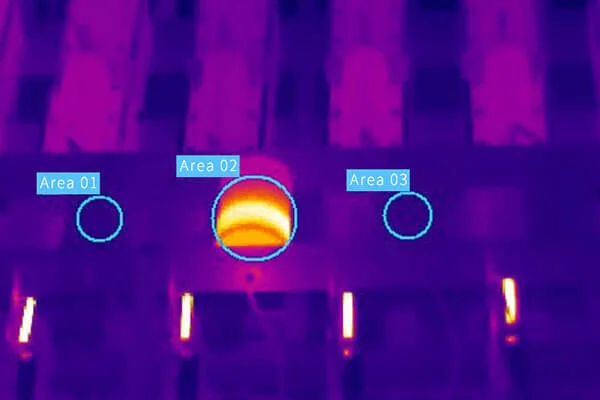

Metallurgical Petrochemical

Thermal imaging technology has broad applications in petrochemical and metallurgy industries, widely used for inspections of steel ladles, blast furnaces, converters, rotary kilns, and key channels. Inspection tools integrated with infrared thermal imaging help with difficult diagnostic challenges and day-to-day predictive maintenance operations.

Solution

On-line Monitoring Systems, Portable Thermal Imager

Key Features

- Support LAN interface: Gigabit Ethernet adaptive

- High precision temperature measurement up to 2000°C with high temperature filter

- Professional thermography analysis: regional analysis, multi-spots measurement

- Isotherm, high temperature alarm, hot spot automatic tracking

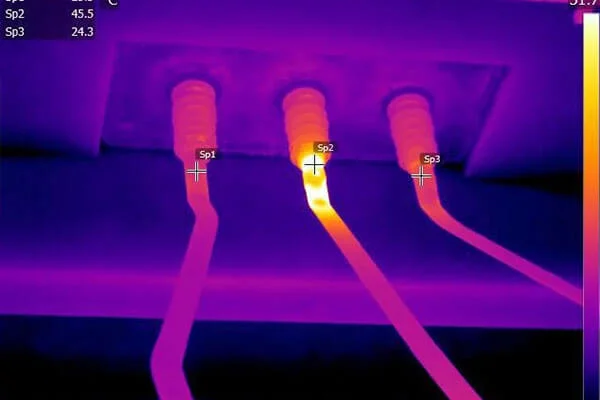

Predictive Maintenance

Infrared thermal imaging technology features real-time, accurate and non-destructive measurement. It enables condition monitoring and defect diagnosis while equipment is still running. It helps quickly locate hot spots, determine problem severity, and establish repair timeframes, greatly avoiding the risk of sudden equipment failure.

Solution

On-line Surveillance, Robots, Portable Thermal Imager

Key Features

- Support LAN interface for flexible networking

- High precision temperature measurement

- Professional thermography analysis

- Extremely compact and portable design

- Low cost solutions available

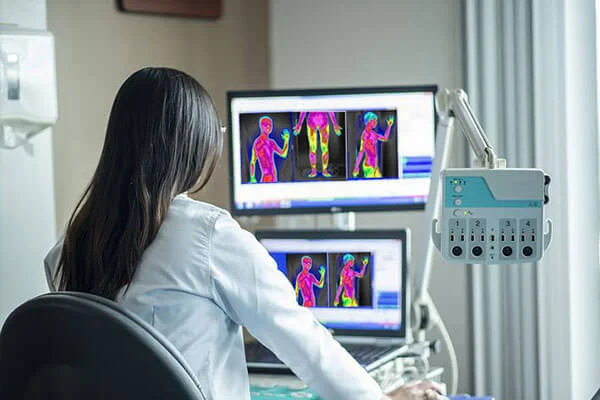

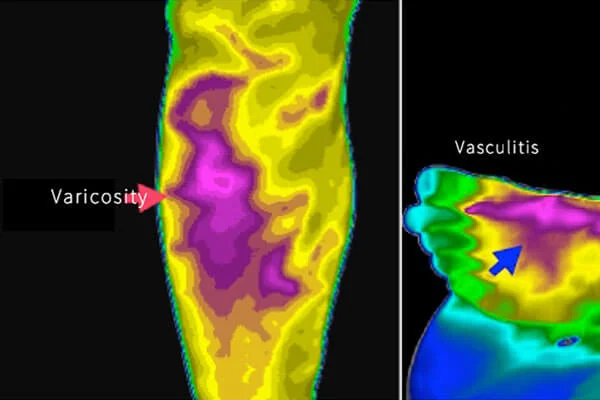

Medical Diagnosis

Painful diseases often show significant body temperature differences in lesion regions, such as acute/chronic shoulder and neck pain, cervical spondylopathy, lumbar spondylosis, and myofascial pain syndrome. Infrared thermal imaging technology has unique diagnostic value by presenting thermal images indicating temperature distribution.

Solution

On-line Monitoring System

Key Features

- Pseudo-color visual enhancement for blood vessels and lesions location

- High precision <±0.5°C, surface uniformity <0.3°C

- Non-contact real-time temperature measurement

- 51.8°×40° wide FOV diagnosis

- Nondestructive, non-radioactive, non-invasive

Explore More Solutions

Discover our complete range of industrial thermal imaging solutions.

View All Solutions