Services & Support

Professional thermal imaging solutions and expert technical support

“Core” Services with Self-independent Infrared Detectors

After years of industrial application experience, ChengJing Technology is capable to provide professional, efficient and convenient solutions for customers in different industries.

Both uncooled and cooled IR detectors in different formats and pixel size

Three production lines with annual production capability up to millions of detectors.

World-leading technology in infrared industry

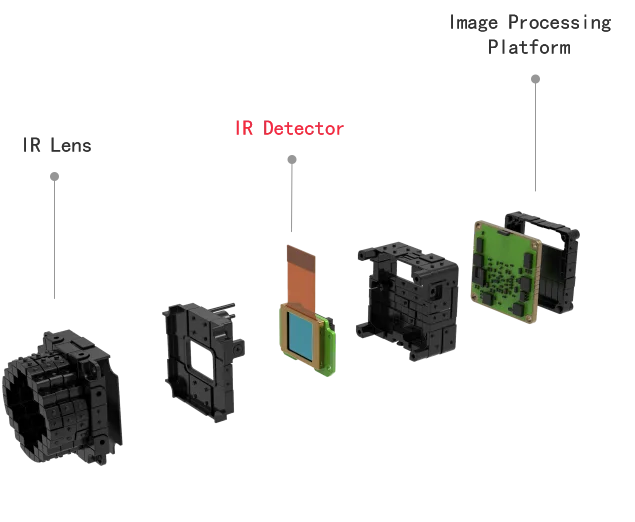

Not Only IR Detector, but ONE-STOP Solution

The Infrared Platform developed by ChengJing covers every component in a complete infrared camera, including IR lens, IR detectors, hardware & processing electronics, software & solutions. Each part is designed as standard module for flexible integration combination. ChengJing is open to share its application experience accumulated in the past 10 years to support our partners to design their own complete infrared products easily, economically and efficiently.

Frequently asked questions

Q1: What is infrared thermal imaging?

Infrared thermal imaging is a method of using infrared radiation and thermal energy to gather information about objects, in order to formulate images of them, even in low visibility environments. It's based on the fact that all objects emit infrared radiation depending on their temperature.

Q2:What is thermography?

Thermography is a non-invasive diagnostic method, based on object surface temperature detection. The infrared (IR) radiation emitted from an object is captured by an infrared camera and converted into thermal images or thermograms showing temperature distribution patterns.

Q3: What is the advantage of infrared thermal imaging?

- See through total darkness

- Identification under camouflage

- Long range detection

- Heat distribution detection

- Non-contact temperature measurement

- Occupation awareness

Q4: What is infrared detector/thermal imaging sensor?

Infrared waves cannot be seen with the human eye. Infrared detector/thermal imaging sensor is an optical-electrical device to react to infrared radiation and convert the detected radiation into measurable electrical signals for subsequent signal processing and image display.

Q5: What is the difference between uncooled and cooled IR detectors?

There are currently two types of infrared thermal imaging sensors on the market, cooled and uncooled.Uncooled IR detectors operate at ambient temperature without additional cooling system, featuring lower cost, smaller size, lighter weight and lower power consumption. Cooled IR detectors need to be cooled to cryogenic temperatures (typically 77K) by built-in cryocoolers for higher sensitivity and faster response time.

Q6: What is thermal imaging module?

There are currently two types of infrared thermal imaging sensors on the market, cooled and uncooled. Uncooled IR detectors operate at ambient temperature without additional cooling, making them cost-effective, compact, and energy-efficient. Cooled IR detectors require cryogenic cooling for enhanced sensitivity. A thermal imaging module integrates the detector with optics and electronics into a complete imaging solution.

Q7: What is NETD?

NETD refers to "Noise Equivalent Temperature Difference". It is a measure of how well a thermal imaging detector is able to distinguish between very small differences in thermal radiation in the image. The lower the NETD value, the better the thermal sensitivity of the detector.

Q8: What is SWaP3?

SWaP3 refers to size, weight, power, performance and price. It indicates the technology trend of infrared industry.

Q9: What is DRI?

DRI usually refers detection, recognition and identification distance of a thermal imaging system. It is a crucial parameter to judge the performance of a thermal imaging system, especially in security and surveillance applications.

Q10: What is WLP? What's the advantage of WLP?

WLP refers to wafer level package. Together with metal package, ceramic package, they are the 3 main package formats of uncooled infrared detectors. WLP offers significant advantages including smaller size, lower cost at high volumes, and better integration possibilities for consumer applications.